What can DH do?

Oil Dehydration units (DH) remove water from oil.

The water in the oil would cause various hydraulic problems.

When oil contains water, the electrostatic oil cleaner (EOC) determines it is no good, and so it stops working. Water contained in oil initiates rusting of metals by adhering itself to the metal surface. The rusts are released into oils and act as catalysts to accelerate oxidation reaction of oils, i.e., presence of water makes oxidation rate by a few tens to a few hundreds of times. To solve this problem, we developed the DH unit that separates out water content. We manufacture two types, water-absorption and water-separation type.

Efficiently remove water content from oil. increase the equipment availability factor.

Mischief-making of water

Once water migrates into oils, mischief-making of water occurs as follows:

・Rusts appear.

・Oil oxidation reaction accelerates, and malfunctions of hydraulic devices will occur.

・Lubrication capacity declines and friction increases.

However little, when water constantly migrates into a system, it accumulates to a large extent. DHS-KS is powerful for such case.

DH Series

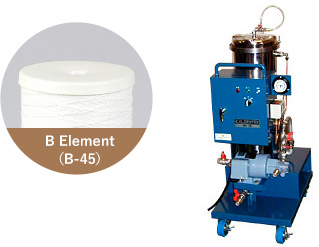

DH-1B (Water-absorption type)

【Water-absorption type】

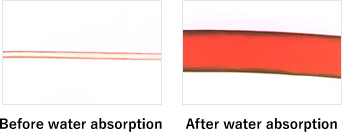

Fiber element of high water absorbance in use absorbs water by several times as much as its own weight. This unit is utilized when the water content is less than 2000ppm and down to 500ppm.

Enlarged photo of fibers

【Applications】

・Removal of the water mixed in the hydraulic oil

・Removal of the water mixed in the lubricant oil for compressors or vacuum pumps

DH-KS・DH(DHS)-2KS/4KS (Water-separation type)

Are you having problem with water migrating into oils?

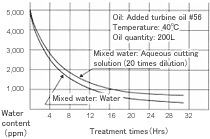

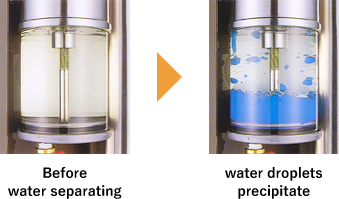

If so, Kleentek’s DH-KS can help you. Even if you have hopeless situations such as aqueous cutting oils with water mixed-in, DH-KS can remove water. This is because we developed method cleverly combining new materials. Emulsion, however persistent, can be decomposed easily to separate and isolated water is automatically discharged as detected by a sensor.

Element

Graph

【Water-separation type】

The aggregating elements made of a specialty material convert emulsified water to larger droplets followed by formation of a water curtain by the separating elements, and the water thus isolated precipitate out to separate. This type of unit is used when water is contained over 2000ppm or constantly entering, and removes water down to 1000ppm.

【Applications】

・Removal of mixed-in aqueous cutting fluids in the hydraulic oils for manufacturing machines.

・Removal of mixed-in water from the lubricant oils for compressors or vacuum pumps.

・Removal of mixed-in sea water in the hydraulic oils for marine machinery such as winches and dredgers.

・Removal of water mixed into the lubricant oils via steam used for steam engines and turbines.

However little, when water constantly migrates into a system, it accumulates to a large extent. DH-KS is powerful for such case.

※ Water separation/absorption type [DH(DHS)-3KSB・6KSB] : This unit, comprising absorption and separation types, removes majority of water via aggregating and separating elements.

| Model | Power consumption (W) |

Dimensions (L×W×Hmm) |

Weight (kg) |

Oil quantity (ℓ) |

Applicable water content |

| DH-1B | 100 | 535×375×940 | 50 | 2,000(~12,000) | < 2,000ppm |

| DH-KS | 75 | 200×300×640 | 27 | 400 | < 10% |

| DH(DHS)-2KS | 200 | 750×400×975 | 78 | 1,000 | < 10% |

【Pump rate】1.2/1.4 liter/min (at 50/60Hz)

【Power requirement】75W,200V, three phase(optionally available for 100V, single phase)

【Cautions】

1. If the mixed-in water is acid, absorbing capacity decreases.

2. It is difficult to handle oils with viscosity greater than 68cst and too much contaminants.

3. It is sometimes difficult to handle oils with surfactants.

4. Model types may be different depending on water content in oils and oil types. Please consult us first.

Electrostatic Oil Cleaner with Dehydration units